Energy Conservation in Enterprises-Main Directions:

- Save energy

- Reduce heat and steam loss

- Reduce the loss of steam lines

Enterprise Energy Saving-Energy Saving Methods

- Selection of Optimal Electricity Price Category and Revision of Power Supply Contract Clauses

- Motor optimization

- Inverter installation

- Optimize the compressed air system

Choose the best price category for the power supply

There are six power supply price categories, and companies can purchase electricity from guaranteed suppliers based on these prices.

All small companies with an installed capacity of less than 670 kilowatts fall into the first category of prices when signing an automatic power supply contract.

All enterprises with installed capacity of more than 670 kilowatts are automatically classified into the third price category.

The first and third price categories are not always the most optimized and cheapest power supply categories.

In some cases, switching to a different price category can reduce electricity costs by 5%-30%.

The topic of price categories is quite broad. In our review of price categories, we detailed how to correctly calculate and select the price category of power supplies.

In addition to price categories, we also recommend carefully reviewing other aspects of the power supply contract:

- Voltage level,

- power,

- Transmission fees.

In our review, you can learn about these and other ways to reduce energy costs.

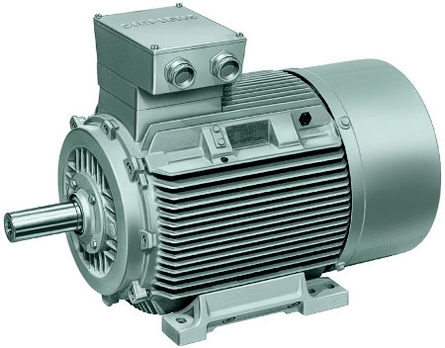

Enterprise Energy Saving-Electric Motor

It is necessary to consider all equipment using electric motors:

- Pump,

- compressor,

- Fans,

- Mechanical tools,

- production line.

Motor control scheme

The motor control plan should be an integral part of the factory's energy saving plan.

Such a plan will help implement a long-term energy-saving system for all motors in the company.

The motor control plan will ensure that failures and failures will not occur, and if they occur, they will be resolved quickly and effectively.

Steps to create a motor control plan:

- Inventory all engines in the facility.

- List the main parameters, technical conditions and service life of the engine.

- Develop general instructions for performing repairs.

- Develop preventive maintenance, lubrication and inspection guidelines.

- Create a safety stock of commonly used spare parts.

- Create procurement specifications for the new engine.

Rewind motor

Generally speaking, it is much cheaper to rewind an old motor than to buy a new one.

If the cost of rewinding the motor exceeds 60% of the cost of the new motor, the motor should be replaced.

Then everything will depend on how the rewind is performed.

If work is done at the highest level, the motor will only lose 1%-2% of its efficiency.

If the rewinding is not done well, the losses in the motor will increase by 5%-10%.

When the motor runs for more than 2000 hours a year, it makes sense to replace the old motor with a new energy-saving motor.

The investment payback period of the new energy-saving engine does not exceed 1. 5-2 years.

Realize enterprise energy saving by increasing load rate

The load factor is the ratio of operating power to apparent power.

This is the way of energy efficiency.

The higher the load factor, the higher the efficiency of power usage.

The motor works best at a load of 75% and above.

Therefore, installing a motor above the required power (for safety reasons) is not only more expensive, but also inefficient in terms of energy consumption.

The load factor can be increased as follows:

- Turn off the unloaded engine,

- Replace the engine with a load of less than 45% for the less powerful model,

- Redistribute the load among existing motors.

Variable Frequency Drive (VFD)

The installation of variable frequency drives only makes sense for dynamic systems.

For example, in static systems involving lifting loads, the installation of variable frequency drives will not help, and will often cause harm.

The VFD balances the load and speed of the motor to ensure the best use of electricity.

VFD can reduce the energy consumption of the motor by at least 5% and at most 60%.

The payback period of VFD investment is usually 1-3 years.

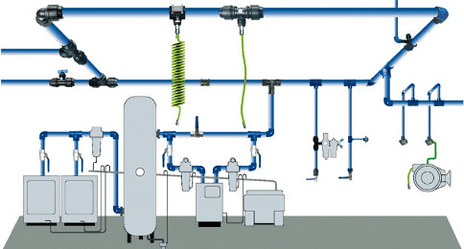

Optimization of compressed air system

Compressed air is used in various industries.

In some companies, compressed air is the main consumer of electricity.

Compressed air is used in pneumatic devices and equipment, conveyor belts, and automatic production lines.

The use of compressed air is very popular because it is a convenient and safe energy source.

But many people forget that compressed air is one of the least efficient energy sources-only 5% of the electricity used for compressed air production is converted into useful work, and the remaining 95% goes into the pipeline.

Enterprise energy saving-compressed air:

- Do not use compressed air to clean the place.

- Reducing the compressor inlet air temperature by 3% can reduce power consumption by 1%.

- For these technical processes, where possible, reduce the compressed air pressure to a minimum. Pressure is reduced by 10% and power consumption is reduced by 5%.

- Regularly inspect and repair compressor equipment and compressed air transmission lines. First, even the smallest compressed air leakage can sometimes reduce the efficiency of the equipment.

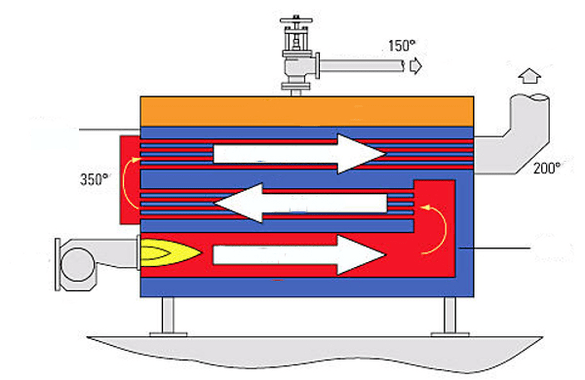

Enterprise energy saving-we reduce heat and steam loss

Steam is often used in industries, especially textile, food and processing industries.

Improving the efficiency of steam boilers and reusing the heat generated can significantly reduce the energy consumption of these plants.

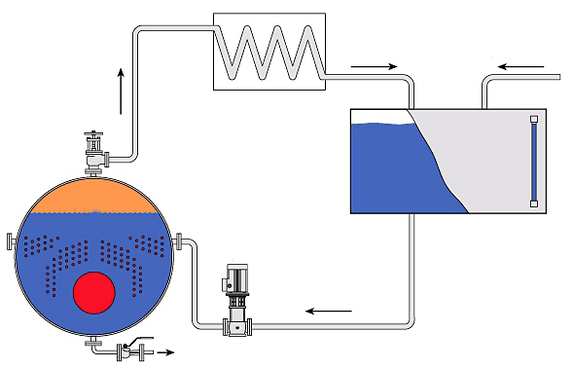

Steam production

The boiler works most efficiently at full power.

Since the demand for steam will change over time, the boiler will often work below its optimal load.

Due to declining product demand or unrealized expansion plans, the installed boiler capacity may be much higher than the company's needs.

In addition, due to the improvement of the production process or the introduction of energy-saving measures, the boiler capacity may not be required.

In this case, the boiler is either operating under full load or operating in a short switching cycle mode.

Both of these conditions can cause significant energy loss.

There is no simple and cheap solution to this problem.

The simplest option isInstall a "small" boiler that can work at full capacityIn the case of average or low workload in the enterprise.

Although this is not a cheap solution, the payback period for this investment may be less than two years.

Moreover, in general, it is always more efficient to have multiple interchangeable small boilers, especially in companies with constantly changing demand or seasonal fluctuations in heat and steam consumption.

Automatic adjustment system

If the company has several boilers, then the installation makes senseBoiler load automatic adjustment system. . .

Automation responds to the enterprise's demand for steam, redistributes the load between boilers, and turns the boilers on or off, thereby significantly improving the efficiency of the entire system.

gate

In businesses where boilers are regularly shut down due to reduced steam demand, the heat loss through the chimney can be quite high.

Can prevent the loss of hot air through the chimneyBy installing gate valvesClose the pipe when the boiler is off.

Prevention and maintenance

If left unattended, the burner and condensate return system may quickly deteriorate or malfunction.

This will reduce the efficiency of the boiler by 20%-30%.

A simple maintenance plan-ensuring that all boiler components are operating at the highest level-will significantly improve operating efficiency.

In practice, regular maintenance can reduce boiler energy consumption by 10%.

Insulation-The heat loss of a properly insulated boiler surface should be less than 1%.

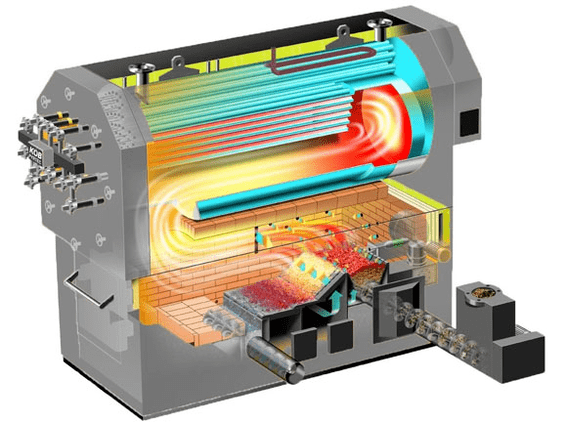

Remove soot and limescale

It is necessary to continuously monitor and eliminate the soot on the boiler tube and the scale in the boiler.

The 0. 8 mm thick soot layer reduces heat transfer by 9. 5%, while the 4. 5 mm thick soot layer reduces heat transfer by 69%!

When calcium, magnesium oxide and silicon are deposited on the boiler heat exchanger, scale will form.

1mm thick scale increases energy consumption by 2%.

Soot and scale can be removed mechanically or acid.

The formation of soot and scale can be determined by the increase in flue gas temperature or visual inspection when the boiler is not in operation.

If the boiler is operated on solid fuels (coal, peat, firewood), the formation of soot and scale must be monitored particularly carefully.

Gas boilers are not prone to smoke and dust problems.

Boiler blowdown optimization

Boiler blowdown is to discharge boiler water to remove impurities and salt in the boiler.

The purpose of boiler blowdown is to avoid or reduce the formation of scale.

Insufficient blowdown of the boiler can cause water to enter the steam or form deposits in the boiler.

Excessive blowdown means loss of heat, water and chemicals.

The optimal blowdown level depends on the type of boiler, the working pressure of the boiler, the preparation and quality of the water used.

The first thing to pay attention to is the preparation of water. If the water is well treated (low salinity), the sewage rate can reach 4%.

If there are foreign matter and salt in the water, the sewage rate is 8%-10%.

The automatic sewage system can also significantly reduce energy consumption.

The payback period of such systems is usually 1-3 years.

Reduce smoke emissions

Excessive smoke is usually the result of air seeping into boilers and chimneys through leaks and openings.

This reduces heat transfer and increases the load on the compressor system.

Leaks and holes are easy to eliminate, requiring only regular visual inspections of boilers and chimneys.

Air conditioning

The more air used to burn the fuel, the more heat is dissipated in the wind.

For safety reasons, a slightly higher amount of air than the ideal stoichiometric fuel/air ratio is required to reduce NOx emissions, and depends on the fuel type.

Boilers with poor technical conditions can use up to 140% of the extra air, resulting in excessive flue emissions.

An efficient gas burner requires 2% to 3% supplemental oxygen, or 10% to 15% supplemental air, to burn fuel without producing carbon monoxide.

The general rule of thumb is that for every 15% reduction in additional air, the boiler efficiency will increase by 1%.

Therefore, it is necessary to check the fuel/air ratio frequently.

This activity does not cost money, but the effect is very good.

Smoke emission monitoring

The oxygen content in the flue gas is the sum of the extra air (added to improve safety and reduce emissions) and the air that penetrates the boiler through holes and leaks.

If a monitoring system is established for the oxygen content in the incoming air and flue gas, the presence of leaks and holes can be easily detected.

Using data on the amount of carbon monoxide and oxygen, the fuel/air ratio in the boiler can be optimized.

Installing a flue emission monitoring and analysis system usually pays for itself in less than a year.

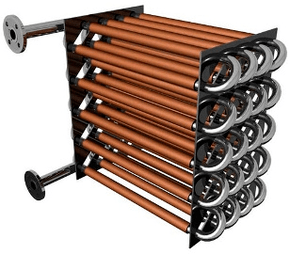

Enterprise Energy Saving-Install Energy Saver

The heat from the flue gas can be used to heat the water entering the boiler.

The heated water enters the boiler and requires less heat to be converted into steam, thereby saving fuel.

Every time the flue gas temperature decreases by 22°C, the boiler efficiency increases by 1%.

The economizer can reduce fuel consumption by 5%-10% and will pay for itself in less than 2 years.

Heat exchanger for extracting heat from boiler blowdown water and steam

The heat exchanger will help recover about 80% of the water and steam heat in the boiler blowdown.

This heat can be used to heat buildings or heat water supplied to boilers.

Any boiler with a constant blowdown rate of 5% or higher is an ideal choice for heat exchangers.

If the sewage system is not operating in constant mode, it makes sense to consider converting it to constant mode while installing the heat exchanger.

The average payback period of heat exchangers will not exceed 1. 5-2 years.

Install condensing economizer

The hot condensate can be returned to the boiler, saving energy and reducing the need for treated water.

The condensing economizer can increase the system efficiency by an additional 10%.

The installation of this economizer should be carried out under the close supervision of experts, who will consider all the nuances of this system, its impact on the boiler and the chemical composition of the water.

Using a system that returns condensate to the boiler can usually pay for itself within 1-1. 5 years.

The system that directs the condensate to the hot water supply can pay for itself in less than a year.

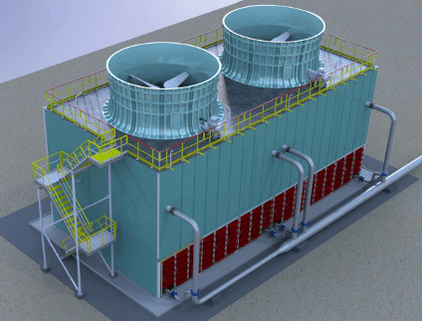

Cooling tower (cooling tower)

A cooling tower is a type of heat exchanger in which water is cooled by air flow.

In terms of energy efficiency, a cooling tower is a device that discharges heat into the wind.

Energy saving potential of cooling tower:

- In some companies, it makes sense to abandon cooling towers altogether. In many cases, heating is used to heat the room while cooling towers are used to dissipate heat. Installing a heat pump will solve the heating problem and at least partially reduce the need to use cooling towers.

- Installing circuit breakers for cooling tower fans can reduce energy consumption by 40%.

- Replacing aluminum or iron fans with new fans (glass fiber and plastic molded) can reduce energy consumption by up to 30%.

Reduce the loss of steam lines

Disconnect unclaimed steam lines

The demand and consumption of steam are constantly changing.

This will cause the entire steam distribution system to not be used at full capacity, only 20%-50%, which inevitably leads to heat loss.

Obviously, optimizing or reconfiguring the entire steam distribution system to meet new demands will be very expensive and may not be feasible.

However, identifying and shutting down steam lines that are hardly used is a very effective energy saving measure.

Enterprise energy saving-pipe insulation

Insulated steam pipes can reduce energy loss by up to 90%.

This is one of the fastest energy savings in the steam distribution system.

The average payback period for heat preservation of pipes that transport steam or hot water is about 1 year.

Condenser pipe 1. 5-2 years.

Steam trap monitoring

A simple steam trap technical condition monitoring program can significantly reduce heat loss.

For example, if there is no maintenance for 3 to 5 years, then about a third of the traps will usually fail, allowing steam to seep into the condensate drain system.

From a practical point of view, in companies with steam trap monitoring procedures, no more than 5% of steam traps have failed.

The average payback period for replacing or maintaining a steam trap is less than six months.

Steam trap monitoring programs usually reduce steam loss by 10%.

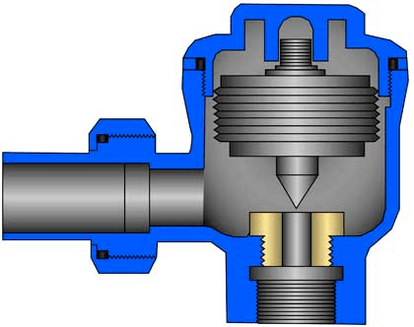

Thermostatic steam trap

The use of modern thermostatic steam traps can reduce energy consumption and improve the reliability of the entire system.

The main advantage of thermostatic steam traps is that they

- Turn on when the temperature is close to the saturated steam level (+/- 2 C °),

- It emits non-condensable gas every time it is opened, and

- The system is in an open-circuit state at the beginning of operation to ensure its rapid temperature rise.

In addition, these steam traps are very reliable and can be used in a wide pressure range.

Disconnect the steam trap

You can reduce energy consumption by closing the steam trap on the superheated steam line when not in use.

Eliminate steam leakage

A small hole steam leak repair program can pay off in less than 3 to 4 months.

We must not forget that small leaks can be ignored for many years and continue to damage the system.

Reuse of condensate and steam

When the steam trap discharges condensate from the steam system, the pressure drop will generate steam from the condensate.

This steam together with condensed water can be used in a heat exchanger to heat feed water or air.

Most importantly, this steam and condensate can be used close to the point of release, because the cost of creating a separate piping system to transport it to the point of use can be very high.